November 1, 2024

Analysis of precision machining technology of modern mechanical design and manufacturing process

Machinery design and manufacturing is a key industry that greatly influences economic speed, development quality, and transformation. The application of diverse production technologies in mechanical design directly impacts the manufacturing industry’s development. Currently, the machinery manufacturing process integrates new technologies and equipment, enhancing automation, intelligence, precision, and speed. This positively affects the modernization, scale, and quality development of machinery manufacturing.

Modern mechanical design and manufacturing processing technology characteristics

1. Flexibility

Flexible production is one of the core features of modern industrial processing. The introduction of automation equipment, such as industrial robots and digital machine tools, improves production efficiency and human-machine interaction, while flexible manufacturing units and automated production lines promote automation and lay the foundation for flexible mechanical production.

2. High precision

Precision is the primary goal in modern manufacturing, with rising market demand for high-precision products. Automation and intelligent technology enable precise control of the production process, ensuring continuous product quality improvement to meet market needs.

3. Strong correlation

In the production design of mechanical products, the focus is not only on process technology. The content of mechanical design and manufacturing technology has become an important factor affecting product sales and market feedback. Therefore, the close relationship between mechanical design market demand, and consumer demand is crucial to the development of enterprise business. To stay competitive, enterprises must enhance production technology to better meet market demand.

4. Combination

Modern mechanical design and manufacturing often require combining multiple production processes to achieve the desired effect t. A modern mechanical production enterprise commonly combines information technology with manufacturing technology effectively. Through the combination of processes, can significantly improve the accuracy of production control, and promote the realization of the goal of precision machining.

Analysis of modern machinery manufacturing technology

1. Automated welding

Modern machinery manufacturing commonly uses automated welding technology.In automatic welding, shielding gas around the arc protects the welding head and workpiece, preventing air interference and ensuring proper arc combustion.

Also included in automated welding technology is the gas welding process. This process combines a programmed program with improved welding confinement, heat preservation in a closed environment, control of tempering temperature for stress relief, and post-welding treatment after cooling. The automatic welding control system manages parameters like welding wire and arc through a PLC system.

In addition, semi-automatic welding technology is also an important part of automatic welding. This welding process requires manual operation, with a melting depth of up to 20mm or more on one side, typically without open beveling. The machine feeds the welding wire, while the operator controls the welding arc. In modern machinery manufacturing, more and more companies tend to use fully automated welding modes.

2. Automated calibration of rough-turning cylinders

The principle of Blank Turning Round Automation Calibration is as follows: The workpiece is placed at both electrode ends, connected to the power supply, and the welded contact areas quickly melt due to the “electric long effect.” Subsequently, we apply a certain amount of pressure to realize the welding effect. The PLC control system and the program effectively control welding current and time to ensure proper fusion dimensions and joint strength.

For a 55mm diameter, 2-meter-long workpiece, the system automatically clamps and aligns the blank on the chuck. Next, we place the turning tool in the four-sided tool table and clamp it after centering it with the top center. We align the tool according to the direction of the end face of the blank and its base. We remove the excess material as the tool approaches the center, then switch the chuck and replace the centers. Finally, we automate the manufacturing process by rotating the tool table.

3. Intelligent manufacturing process of stud welding

Stud welding is a common method in mechanical design and manufacturing, with two main types: energy storage and arc pulling. The energy storage type suits thin plate welding with a small fusion depth, while the arc pulling type, which offers a larger fusion depth, is used in heavy industry. This process is simple and avoids issues like drilling, bonding, or leakage in weldments.

In the intelligent production process, the system integrates several sensors and regulators to actively monitor the production status.The system steps down power using a transformer and converts AC to DC with a rectifier bridge. In addition, bidirectional current tubes and charging resistors provide power support for the capacitors. Intelligent technology in smart chips allows energy storage capacitors to efficiently release power for automated welding, improving precision, and efficiency, and advancing the industry.

Application of modernized mechanical design and manufacturing precision processing technology

The domestic market is growing quickly, and mechanical production enterprises must adapt to rising demand and improve manufacturing precision. Therefore, the relevant enterprises should grasp the needs of market-oriented development, modernization, and development-oriented, explore the application of precision machining technology in mechanical design and manufacturing, promote the continuous improvement of mechanical design and manufacturing quality, and accelerate the healthy and steady development of enterprises.

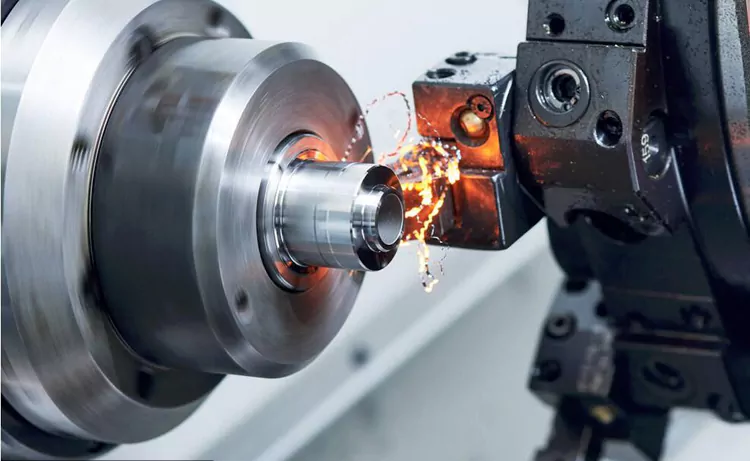

1. Cutting technology

Cutting technology processes the original material appropriately to ensure production accuracy in mechanical manufacturing.As market demands for machining accuracy increase, traditional cutting technology struggles to meet these needs, requiring breakthroughs to reduce the impact of tools on workpiece processing.

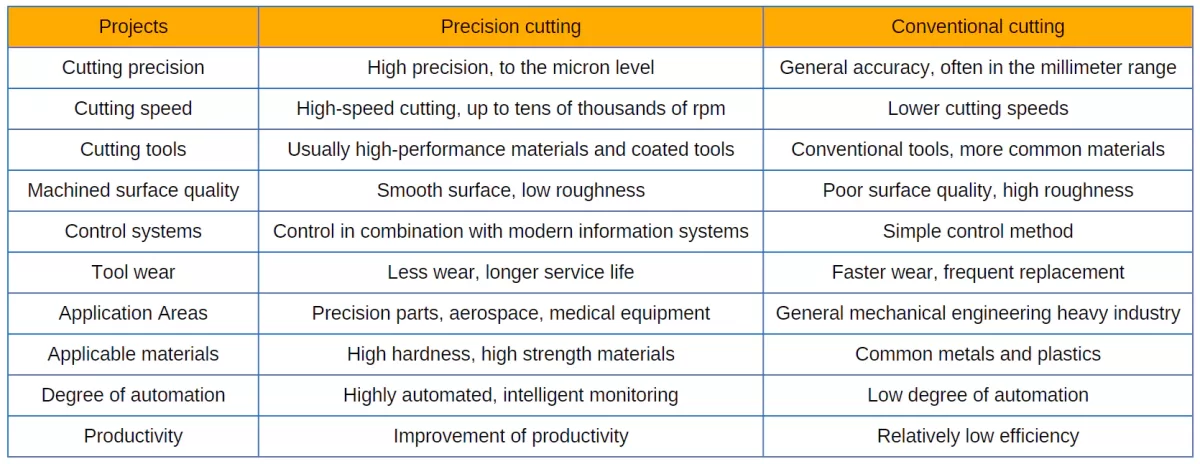

Comparison of precision cutting technology and traditional cutting technology

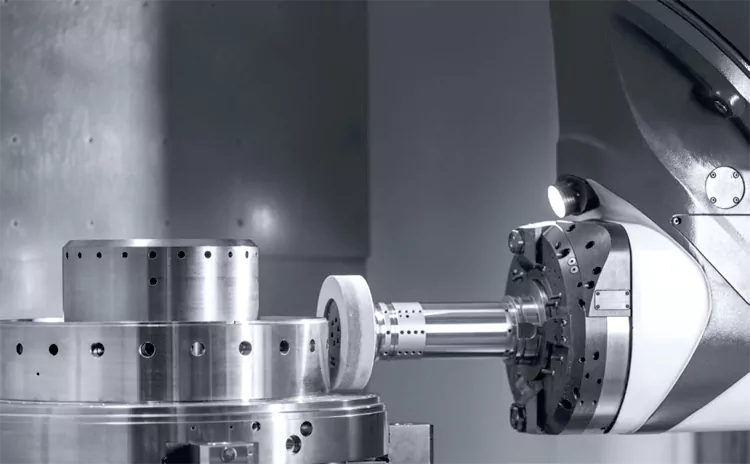

Precision cutting technology is a modern cutting technology. With the continuous progress of machine tool technology, the cutting speed has reached tens of thousands of revolutions per minute. Precision-cutting technology reduces tool impact on machines, ensuring workpiece accuracy. Combining cutting technology with modern information systems enables effective control, improving cutting precision.

In mechanical manufacturing, the use of cutting tools is key to the control of workpiece processing accuracy. Modern parts finishing technology ensures workpiece accuracy and promotes overall production automation. This is essential to improve the efficiency of workpiece handling in machining.

Boosting productivity can be challenging, considering the space constraints in a machining plant. Traditional machining shortcomings can be addressed by optimizing the part’s axial surface, improving smoothness, and using CNC polishing equipment.

In mechanical manufacturing processing, it is critical to select the right technology to support production and ensure processing quality. In addition to choosing the right processing technology, it’s essential to control precision, meet quality standards, and ensure that production personnel are technically competent to maintain processing quality.

2. Grinding technology

Grinding technology is widely used in the production and processing of silicon wafers. Manufacturers must control the surface roughness of the silicon wafer at 0.1–0.2 microns and make polishing adjustments to meet production requirements. As precision requirements rise, traditional grinding technology can no longer meet the demands, leading to the adoption of precision grinding technology in modern mechanical processing.

At present, the grinding technology commonly used in mechanical processing includes:

- Flow pressure type suspension grinding technology

- Mechanochemical grinding technology

- Elastic emission grinding technology

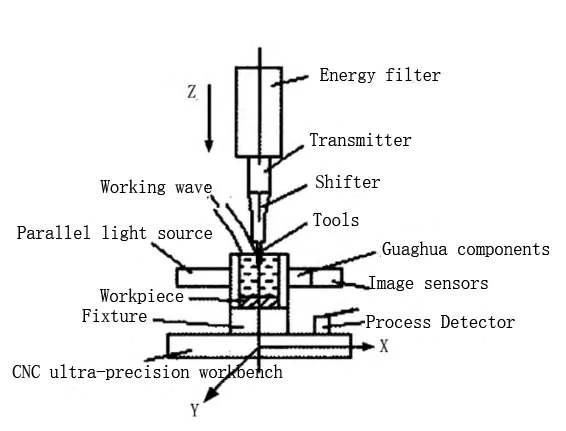

Ultra-precision grinding technology avoids direct contact with the workpiece, reducing the adverse effects of grinding equipment on the surface and structure. This method improves precision, minimizes surface roughness, and ensures the quality of mechanical products. As shown in Figure, it is the structure of an ultra-precision grinding experimental system.

Structure of ultra-precision grinding experiment system

By constructing an ultra-precision grinding system, the workpiece avoids direct contact with the grinding tool, improving processing accuracy and quality by preventing friction and external forces from affecting the surface.

3. Micromechanical technology

Compared to traditional mechanical types, micro-mechanical technology offers faster response, simpler operation, and higher processing accuracy, making it widely used in production and processing. Its application in piezoelectric components is common, with electrostatic motors as the core technology. Micromechanical products are usually small in specification, but their information-capturing ability is very powerful.

The processing of microelectronic components is crucial for mechanical parts like profitability and speed detection. Micro-mechanical technology demands high precision, requiring the integration of control and transmission technologies to ensure accurate processing.

At present, the application of micromechanical technology in modern mechanical design and manufacturing processing is increasing. This technology has significantly improved manufacturing precision, ensuring better alignment with market demand and boosting the competitiveness of machinery manufacturers.

Conclusion

Modern mechanical design and precision machining are essential for ensuring product quality and improving economic efficiency. This paper analyzes common processes in mechanical manufacturing and discusses the role of precision machining in the industry.

Precision machining technology is crucial for enhancing product competitiveness and improving manufacturing quality. Machinery manufacturers must integrate advanced technologies, high-quality processes, and precision machining to improve product quality and standards.