November 11, 2024

Application and optimization of intelligent manufacturing technology in machinery manufacturing industry

The machinery manufacturing industry is crucial to the national economy, and improving its modernization is key to social development. Intelligent technology enhances production efficiency, upgrades product quality, and drives industry transformation.

Intelligent manufacturing technology in machinery manufacturing industry-specific applications

1. Application in design and development

In the machinery manufacturing industry, design research and development is crucial. The traditional design and development process usually relies on the cycle of “design-sampling-modification” until the product design program meets the standard. This process is time-consuming, slows down the production schedule, and may lead to excessive investment and waste of resources. Intelligent manufacturing technology through virtual simulation and 3D modeling, the realization of the digital design process, and virtualized sampling, which helps to quickly find problems in the design scheme, timely modification, and adjustment.

With the help of smart manufacturing technology, designers can directly synchronize modifications on digital drawings, significantly accelerating the design process. At the same time, visualized simulation tests make it easier to show samples and convey design concepts to customers, and if customers have additional needs, they can also make instant adjustments. By fine-tuning the design in the simulation phase, we can effectively avoid parameter errors or non-conformity problems, thus ensuring the feasibility of the design. Using this as the basis for actual prototyping saves resources and greatly improves the efficiency of design and development.

2. Application in production and processing

In traditional machinery manufacturing, manual operation of machines leads to low efficiency and poor quality control. Intelligent manufacturing, integrating automation, computers, and AI, automates production, reduces the need for manual intervention, shortens workflows, and improves product quality. This technology enhances both efficiency and competitiveness in the increasingly competitive industry.

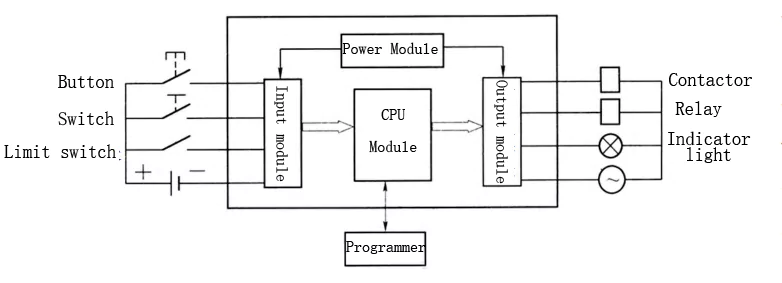

A Programmable Logic Controller (PLC) is widely used in intelligent manufacturing to automate and precisely control production equipment. It reduces reliance on manual labor, enhances safety in hazardous environments, and minimizes human errors. PLC also supports 24/7 production, improving efficiency and resource utilization while helping machinery manufacturers cut costs and boost productivity. The basic structure of a PLC is shown in Fig. 1.

Figure 1 PLC basic structure

In today’s machinery manufacturing industry, the application of automated production lines and robots has become a development trend. Through sensors automation controllers and other equipment, the production line can realize automation and continuity, and support remote control. Robots, on the other hand, take on repetitive or high-risk tasks, significantly improving the safety and reliability of production and processing.

In the production process, product quality control is a top priority. Artificial intelligence technology enables efficient quality management through intelligent inspection and screening. With visual recognition and deep learning, AI systems can recognize product defects and perform quality inspections. For example, the AI model contains a variety of possible defect samples in advance, such as the appearance of scratches, defects, deformation, etc. The automatic inspection system can quickly compare defects and separate unqualified products from the production line to ensure product quality.

At the same time, artificial intelligence with the help of neural networks can continuously learn and improve from the quality inspection data to further optimize the process parameters, thus improving defect detection efficiency and product qualification rate. This process not only improves the detection efficiency but also provides a continuous improvement direction for the production process, which helps to achieve higher quality production standards.

3. Application in troubleshooting

Production equipment failure can severely impact efficiency and profits. Intelligent manufacturing should not only enhance efficiency but also strengthen fault control to ensure stable operations and reduce downtime. Traditional fault handling is reactive, investigating and maintaining equipment after failure, which is inefficient. Intelligent manufacturing enables real-time monitoring and early warnings for proactive prediction and rapid response.

The intelligent fault-handling system uses sensors, communication, computers, and automation. Sensors monitor equipment in real-time, collecting data (e.g., environmental and equipment data) and transmitting it to a central system. The system analyzes the data using algorithms, detecting abnormalities and activating fault detection to locate and analyze the problem. It then sends fault information to technicians for quick resolution.

The intelligent troubleshooting system monitors equipment status, sets maintenance cycles, and alerts staff when maintenance is due, improving reliability, reducing failures, and ensuring continuous production and longer equipment lifespan.

4. Application in management

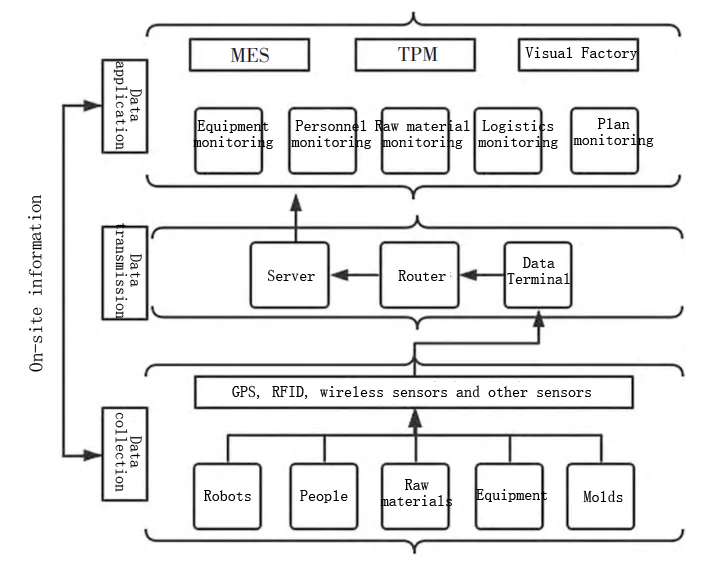

Management is crucial in machinery manufacturing, and scientific management improves production efficiency and economic benefits. The Internet of Things (IoT) and big data play key roles in intelligent manufacturing. Big data provides decision-making data on production, sales, and markets, helping create better production plans and supply strategies while promoting lean supply chain management. It also analyzes costs and resource consumption in production, offering optimization solutions to enhance sustainability and energy efficiency in manufacturing.

IoT technology is widely used in warehousing and logistics management. Through sensors and RFID, it creates identification networks and management systems for raw materials, products, and equipment, building databases and information ledgers. Material inventory can be tracked automatically via chip induction, and when stock levels are low, the system alerts purchasing staff to reorder.

Real-time logistics management uses RFID tags for location tracking (GPS) and environment monitoring (sensors), helping businesses prepare materials in advance, reduce delays between warehousing and production, and improve efficiency. These tools enhance flexibility and competitiveness in machinery manufacturing. The application path of IoT in machinery manufacturing enterprises is shown in Figure 2.

Figure 2 The application path of the Internet of Things in machinery manufacturing enterprises

Optimization direction of intelligent manufacturing technology in the machinery manufacturing industry

1. Control strategy and algorithm optimization

As the machinery manufacturing industry develops, customer demands rise, product structures become more complex, and production accuracy increases. However, China’s intelligent manufacturing technology lags behind developed countries, especially in control strategies and algorithms, which still have significant room for improvement. The optimization of these strategies directly impacts the level of mechanical manufacturing.

Control strategy is key to intelligent manufacturing, ensuring precise control of equipment. Higher precision improves stability, product quality, and production efficiency while reducing errors and equipment fluctuations to maintain consistency.

Algorithm technology is key in optimizing production processes by streamlining operations and improving product quality. For example, optimizing equipment trajectories and flows boosts productivity and cuts costs. As intelligent technology advances, integrating cutting-edge innovations can further enhance control strategies and algorithms.

Visual recognition technology in control strategies enables production equipment to “see,” allowing real-time monitoring and adjustment of unstable factors, enhancing process stability. Algorithmic advancements, such as genetic, fuzzy, and ant colony algorithms, optimize production adaptively, improving equipment trajectory accuracy, simplifying processes, boosting efficiency, and reducing manual intervention and errors.

2. Human-machine cooperative optimization

Intelligent manufacturing technology has optimized human resource use, but human involvement remains essential. Human-machine collaboration is key to improving efficiency, with machines learning and adapting to human operations for better coordination.

The key to achieving this goal is strengthening data collection and analysis. By gathering and analyzing large amounts of data, machines can build a strong foundation for neural networks and deep learning. Learning from human behavior, machines develop more intelligent thinking, improving their perceptual capabilities, analysis, and ability to make autonomous decisions. For instance, machines can adjust based on the production environment or human instructions, optimizing operations inreal-timee. This boosts productivity, flexibility, and safety.

Human-machine co-optimization ultimately maximizes the potential of smart manufacturing by enabling deep collaboration between equipment and operators. Under this collaborative model, the combination of human creativity and judgment with the efficient execution capabilities of the machine can bring about higher production efficiency, reduce human error, optimize the production process, and make the manufacturing process more precise and efficient.

3. Decentralized multi-power optimization

The progress of intelligent manufacturing technology is closely related to the power source output characteristics of production equipment. With the gradual development of machinery manufacturing in the direction of high efficiency, flexibility, and intelligence, the intelligent manufacturing system needs to be able to meet these complex operational requirements, and accurately monitor and control the movement characteristics within the production equipment. In modern production lines, a large number of equipment are usually included, and the power sources of different equipment are often different, which leads to the diversity of each equipment component in terms of movement and control mode. How to realize the coordinated cooperation and precise control between various equipment has become a challenge for intelligent manufacturing technology.

To solve this problem, decentralized multi-dynamic optimization has emerged. Through decentralized multi-power optimization, fine management and control of different equipment in the production line can be achieved. Specifically, this method involves establishing models for different equipment and making uniform correspondence and matching of information in the database. Through precise data analysis and algorithmic optimization, more efficient and accurate motion control of equipment components can be achieved. For example, in the production process, the optimized multi-dynamic control system can automatically adjust the power output according to the characteristics of different equipment to achieve smoother cooperative work.

Decentralized multi-power optimization relies on advanced control technologies and algorithms to match power sources to equipment in different modes, improving efficiency, flexibility, and adaptability across the production line, supporting intelligent manufacturing, and advancing industry modernization.

Conclusion

At present, intelligent manufacturing is the key direction of the development of the machinery manufacturing industry, the relevant enterprises and personnel to strengthen the integration of intelligent manufacturing technology in the design and development of production and processing and other areas, to achieve more efficient, intelligent and environmentally friendly production and management, and at the same time, to further accelerate the development of intelligent manufacturing technology and innovation, to promote the industry’s qualitative and efficient and transformational development.