August 15, 2024

CNC cutting machining size instability how to do

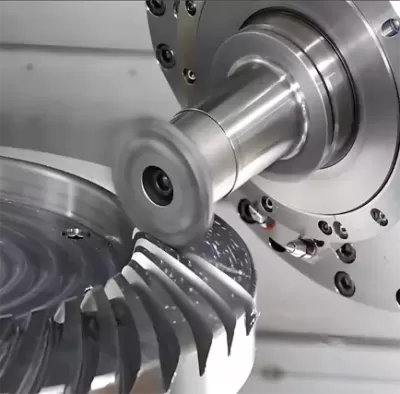

CNC cutting plays an important role in modern manufacturing. Its high efficiency and precision machining capabilities make it widely used in aerospace, automotive manufacturing, mold processing, and other fields. However, CNC technology’s high degree of automation and precision control cannot prevent dimensional instability issues from occurring during actual processing.

These instabilities affect product quality. They may also reduce productivity and increase costs. This article will explore the causes of dimensional instability in CNC cutting. We will also propose targeted solutions to help practitioners improve machining accuracy and stability.

Causes

1. The impact of the workpiece material

- Material heterogeneity: Different materials in the machining process exhibit different mechanical properties. The changes in hardness and toughness affect the stability of the cutting force. This instability results in inconsistent sizes.

- Thermal expansion effect: During cutting, heat may cause the workpiece to expand. Different materials have different coefficients of thermal expansion. This can also lead to dimensional deviations.

2. Effect of tooling

- Tool wear: The tool gradually wears during use. After wear, the tool cannot maintain stable cutting performance, which increases dimensional error.

- Tool geometry angle: An unreasonable tool geometry angle design affects the cutting process. This causes dimensional instability.

3. The impact of the machine tool

- The machine tool lacks sufficient rigidity. The rigidity of the machine tool directly affects processing stability. During cutting, the machine tool may vibrate, causing dimensional errors.

- Temperature changes occur in the machine tool during operation. The heat generated by the machine tool causes small deformations in its structure. If we don’t control this thermal deformation effectively, it will lead to dimensional instability in processing.

4. The influence of process parameters

- Unreasonable process parameter settings can cause uneven tool force, which triggers fluctuations in machining size.

- Improper coolant use affects the temperature of the cutting area. It may also affect the stability of the cutting force. If cooling is inappropriate, thermal stresses may concentrate, causing dimensional changes.

5. Influence of the machining environment

- Temperature and humidity changes: Changes in the temperature and humidity of the machining environment can cause thermal expansion or contraction of the machine tool, cutting tool, and workpiece. These changes can lead to fluctuations in machining dimensions.

- Vibration interference: Mechanical vibration from the surrounding environment can affect the machine tool. This vibration can reduce machining accuracy.

Strategies

1. Material Selection and Pre-treatment

- Material Selection: Before machining, choose suitable materials based on the workpiece’s specific requirements. Pay special attention to the coefficient of thermal expansion and mechanical properties.

- Material Pre-treatment: For materials prone to thermal deformation, apply heat treatment or natural aging. These processes reduce internal stress and improve machining stability.

2. Tool optimization

- Tool material and coating selection: Choosing the right tool material and coating reduces tool wear, extends tool life, and ensures machining stability.

- Optimization of tool geometry parameters: Optimize the geometric angles of the tool based on machining requirements. Adjust angles such as the main offset angle, front angle, and back angle. This reduces cutting force and minimizes dimensional error.

3. Machine tool maintenance and adjustment

- Regular maintenance: Inspect and maintain the machine tool regularly. Pay special attention to calibrating key components like machine guides and screws. This ensures the machining accuracy of the machine tool.

- Thermal deformation control: For machine tools sensitive to thermal deformation, control the temperature consistently. Optimize the cooling system and use other methods to reduce the impact of thermal deformation on dimensional accuracy.

4. Optimization of process parameters

- Reasonable setting of cutting parameters: Set the cutting speed, feed rate, and depth of cut according to the workpiece material and processing requirements. This ensures the stability of the machining process.

- Coolant management: Optimize coolant use and flow. This helps control the temperature in the cutting area within a reasonable range and reduces thermal stress impact on the dimensions.

5. Environmental control

- Temperature and humidity control: In the machining environment, constant temperature and humidity equipment reduces the impact of environmental changes on the machine tool and workpiece.

- Vibration isolation: Install vibration-damping devices on the machine tool foundation. This reduces the influence of environmental vibration on machining accuracy.

Applications

1. Online measurement and feedback control

- Online measurement technology: Install high-precision online measurement equipment to monitor dimensional changes in real-time during the machining process. Adjust process parameters promptly to ensure machining accuracy.

- Closed-loop control system: Apply closed-loop control technology to feed back the online measurement results to the CNC system. This automatically adjusts machining parameters and improves machining stability.

2. Intelligent tool management system

- Tool life prediction: Through the intelligent tool management system, real-time monitoring of tool use conditions, predicting tool life, and timely replacement of tools to avoid dimensional errors caused by tool wear.

- Adaptive tool parameters: According to the actual state of the tool in the machining process, adaptively adjust the geometric parameters and cutting parameters of the tool to optimize the machining quality.

3. Advanced machine tool structure design

- High-rigidity machine tools: develop high-rigidity, vibration-resistant machine tool structures to reduce vibration during machining and ensure dimensional stability.

- Thermal compensation technology: Introduce thermal compensation technology in machine tool design, automatically adjusting the position compensation of the machine tool by real-time detection of temperature changes in various parts of the machine tool to reduce the impact of thermal deformation.

Case

In the CNC machining of an aerospace part, the high-strength alloy of the workpiece caused serious dimensional instability during the cutting process.

A comprehensive analysis of the machining process revealed that tool wear and insufficient machine rigidity were the main causes of the problem. To address this, the technical team took the following actions:

- Substituting the tool with one that has better wear resistance and optimizing the tool geometry helped reduce the cutting force.

- Enhancing the machine tool’s rigidity and adding vibration-damping devices in key areas improved performance.

- Utilizing online measurement technology, they monitored dimensional changes in real-time and adjusted parameters through a closed-loop control system.

After these optimization measures, the final machining dimensional stability of the part improved significantly. The pass rate increased from 85% to 98%.

Summarize

The problem of dimensional instability in CNC cutting machining results from multiple factors. Materials, tools, machine tools, process parameters, and environmental factors all play a role. By considering these factors and introducing advanced measurement and control technology, we can reduce dimensional instability. This will improve machining quality and productivity.

In the future, intelligent manufacturing technology will further enhance the accuracy and stability of CNC cutting machining. This will provide stronger support for the manufacturing industry.

This blog post offers both theoretical analysis and practical cases. It provides practical solutions for practitioners in the CNC machining industry. We hope this article will help improve CNC machining accuracy and stability.