April 10, 2025

Research on Hydroforming of Complex Thin-Walled Sheet Metal Parts

As the manufacturing industry advances, the demand for sheet metal parts continues to grow. Manufacturers now need lighter and more integrated components. At the same time, thin-walled parts are becoming more varied and complex. These changes bring new challenges to design and production.

1. Complex Thin-Walled Aviation Sheet Metal Parts and Hydroforming Technology

1.1 Characteristics of Complex Thin-Walled Aviation Parts

As designers develop new products, they create more complex part structures. They often add features like bosses, ribs, and small fillets to improve performance and save material. Engineers prefer lightweight metals like magnesium, aluminum, and titanium to reduce weight. However, these materials have low plasticity. They often wrinkle or crack during forming (see Figure 1).

Figure 1 Wrinkling and cracking in complex thin-walled sheet metal parts

To solve these problems, engineers must study sheet metal design and forming technology. This research helps them improve accuracy, quality, and efficiency in forming.

1.2 Principles and Features of Hydroforming

Hydroforming uses liquid pressure to help shape metal sheets. Manufacturers use this process widely in sheet metal production. It reduces friction, increases accuracy, and prevents forming defects. It also improves the quality of finished parts.

The liquid acts as a lubricant. It reduces friction and makes the forming process easier and faster. The pressure helps the sheet stick closely to the mold. This allows the metal to form more complex shapes and reduces defects. The process needs hydraulic equipment, CNC control, and a press machine.

1.3 Process Control in Hydroforming

In aviation, forming quality depends on two key factors—liquid chamber pressure and forming stress. As parts become more complex, controlling these factors becomes more difficult. Engineers must manage pressure and tension carefully.

If the pressure is too high, the sheet may wrinkle. If the pressure is too low, the sheet may not form completely. Engineers must find a balance. They also need to study how fluid movement affects stress in different materials. Forming parameters also affect stress, so they must control these variables accurately.

1.4 Advantages of Hydroforming in Complex Thin-Walled Part Production

Hydroforming brings many benefits. It reduces costs, improves efficiency, and produces better parts. It works especially well for thin-walled parts with complex shapes and high precision requirements.

The process uses liquid pressure instead of traditional punches or dies. This reduces tool cost and complexity. Engineers can adjust the pressure and use precise control systems. This helps them achieve high accuracy and better material usage. These features make hydroforming a great choice for modern manufacturing.

2. Hydroforming of 5A06 Aluminum Alloy Thin-Walled Parts

2.1 Material Overview

Engineers often use domestic aluminum-magnesium alloy 5A06 in aviation. This alloy has low density, high strength, good ductility, and strong fatigue resistance. It is also lightweight. These features make it ideal for thin-walled, curved parts that do not need very high strength.

2.2 Forming Process

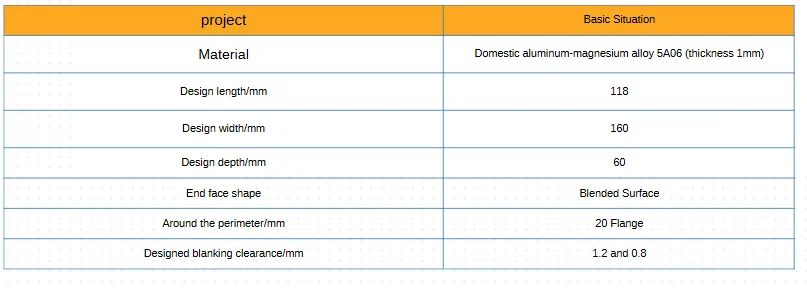

This study looks at a curved protective cover made from 5A06. Table 1 shows the basic information of the part.

Table 1 Basic Information of the Sheet Metal Part

The forming process has some challenges. The sheet is thin and has poor ductility. When forming corners in one step, the sheet often wrinkles or cracks.

2.3 Finite Element Modeling and Analysis

The team used ETA software to simulate the forming process. They used automatic simulation settings, a fixed-gap clamping method, and the Hi-Yield material model. These tools improved the accuracy of the simulation.

The simulation showed that the blank holder gap is critical. If the gap is too small or too large, the sheet cannot flow properly. This affects both shape and quality. The team found that a gap of 1.05 to 1.1 times the sheet thickness gives the best results. They also designed the pressure path in the liquid chamber to keep the pressure uniform.

2.4 Mold Design

The mold includes a die, a punch, and a blank holder. A double-acting hydraulic press applies the forming force. During forming, the punch and blank holder stay fixed. This keeps the sheet in close contact with the mold.

The team injects fluid into the mold’s hydraulic chamber. The pressure pushes the sheet evenly against the die and punch. They control the blank holder forcefully. They also adjust the gap and choose the right materials. These steps improve mold precision, increase production efficiency, and ensure good part quality.

3. Conclusion

To make high-quality thin-walled sheet metal parts, engineers must use advanced forming methods. This study takes a common 5A06 part as an example. It shows how hydroforming works in practice. The results prove that hydroforming is a reliable and effective method for forming complex aviation sheet metal parts.