August 20, 2024

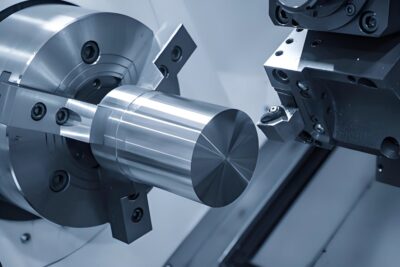

The Future of CNC Machining: Key Trends and Innovations to Watch in 2024

As CNC machining continues to evolve, staying ahead of the curve can significantly impact your business’s efficiency and competitiveness.

In this blog post, we’ll explore the hottest trends and innovations in CNC machining for 2024, providing insights that are crucial for customers looking to leverage this technology.

From advancements in automation to the latest materials, discover what’s shaping the future of CNC machining.

The Rise of Smart CNC Machines

Automation is transforming CNC machining, making processes more efficient and precise. Modern CNC machines are increasingly equipped with advanced sensors, AI-driven controls, and integrated software systems.

These smart machines can self-calibrate, predict maintenance needs, and optimize cutting paths, reducing downtime and enhancing productivity.

For customers, this means higher accuracy and lower costs over time. Investing in automated CNC technology can lead to significant improvements in manufacturing efficiency and product quality.

The Integration of IoT in CNC Machining

The Internet of Things (IoT) is revolutionizing CNC machining by connecting machines and systems through the cloud.

This integration allows for real-time monitoring and data analysis, offering valuable insights into machine performance and production metrics.

With IoT-enabled CNC machines, manufacturers can perform predictive maintenance, minimize disruptions, and improve overall operational efficiency. For customers, this translates to more reliable and consistent production processes.

Advances in Materials and Cutting Tools

The materials and cutting tools used in CNC machining are continually evolving.

In 2024, expect to see increased use of advanced composites, high-performance alloys, and innovative coatings that extend tool life and enhance machining capabilities.

These advancements enable the production of more complex and durable components while maintaining high precision.

As a customer, staying informed about these new materials can help you select the best options for your specific applications and improve the performance of your end products.

Sustainability and Green Manufacturing

Sustainability is becoming a central focus in CNC machining. Companies are adopting green manufacturing practices to reduce waste, minimize energy consumption, and lower their environmental impact.

This includes using eco-friendly materials, optimizing machining processes to reduce scrap, and implementing recycling programs.

For customers, supporting suppliers who prioritize sustainability can align with corporate social responsibility goals and meet increasing consumer demand for environmentally friendly products.

Customization and On-Demand Production

The demand for customization and on-demand production is rising. CNC machining is increasingly used to create bespoke parts and components quickly and cost-effectively.

With advancements in software and machine capabilities, manufacturers can now offer more flexible production options and shorter lead times.

This flexibility allows customers to get precisely what they need without overproducing or waiting long periods, ultimately enhancing the responsiveness and adaptability of your supply chain.

Conclusion

As CNC machining technology advances, staying informed about the latest trends and innovations can give you a competitive edge.

From smart automation and IoT integration to cutting-edge materials and sustainable practices, these developments are shaping the future of manufacturing.

By understanding and leveraging these trends, you can make informed decisions that enhance your production capabilities, reduce costs, and meet evolving market demands.

For more insights into CNC machining and how these trends can benefit your business, reach out to your trusted suppliers and industry experts. Embrace the future of CNC machining and stay ahead in today’s rapidly changing manufacturing landscape.